Maize or corn is the crop that consumes most irrigation water in France. From an agronomic point of view, this plant is very efficient in its use of water, its biomass ratio or yield per quantity of water absorbed being very high. And there is a reason for this: maize (corn) has a so-called C4 metabolism; so it is able to continue its photosynthetic activity even during periods of high temperatures because carbon fixation continues in another compartment of the leaf, even after the stomata have closed.

It is considered that, in order to produce 1 kg of grain maize (corn), only 450 litres of water are needed (250 litres for fodder maize or feed corn). By comparison, 600 litres are required to produce 1 kg of wheat and 900 litres for soya.

Under conditions of very high temperatures, such as those that we have experienced in the summer, maize is one of the plants that use the water resource most efficiently. However, for production to be viable, applications of irrigation water will be essential.

In the face of reduced water resources in the summer, one of the solutions will be improving the quality of the irrigation. Drip irrigation, with its precise localised application, uniformity and very low precipitation rate (lower than 2 mm/h), allows for the water to be applied more efficiently.

THE ADVANTAGES OF USING DRIP IRRIGATION FOR MAIZE (CORN)

• Better use of water (increased yield and/or reduced water consumption).

• Savings on energy, lower operating pressure.

• Savings on water, fewer losses through evaporation or by wind drift.

• Possibility of applying nutrients via fertigation.

• Less inputs (fertilizers in units/ha, plant health care treatment, fewer weeds).

• Less soil compaction.

• Time-saving as a result of the automation of the system.

• Improved grain quality (in terms of the mycotoxin level)

• Adaptable to the different shapes of the fields.

• Discretion and uniformity.

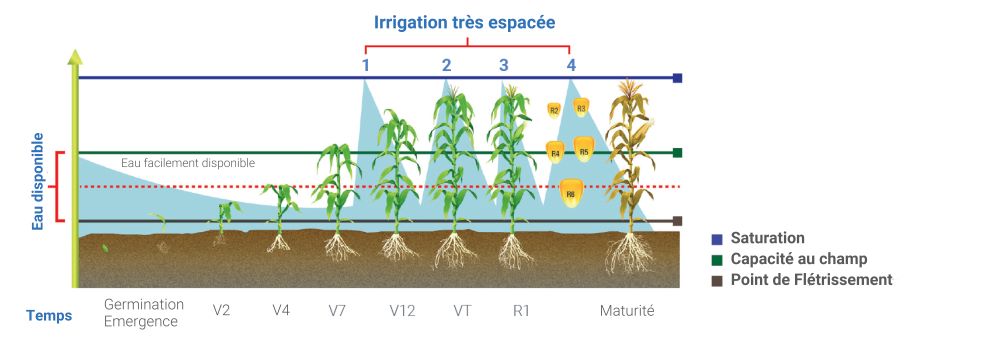

Mobile irrigation system (hose-reel or pivot)

A mobile irrigation system can produce plant water stress, induced by the large fluctuations in the precipitation rate on a long cycle, leading to water losses. Its efficiency is between 50 and 85%.

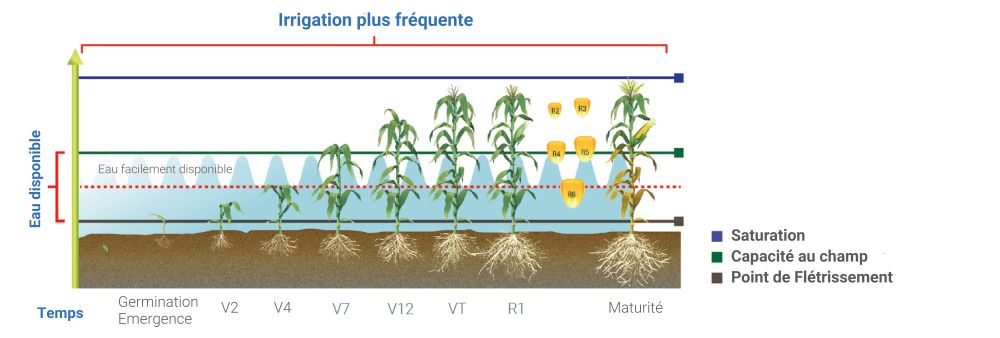

Drip irrigation

Drip irrigation helps to prevent plant water stress, allowing for a balance to be achieved betweeen the water, atmosphere and the nutrients; its efficiency is 90%

There are two types of drip irrigation devices for the maize or corn crop, i.e. drip lines rolled out on the surface and drip lines buried in the soil.

Subsurface drip irrigation

The subsurface irrigation system, although it has been around for several decades now, is still considered as being the most innovative on the market. It is practised by producers who have opted for shallow cultivation techniques. The pipes are buried at an average depth of 30 cm. The pipe is designed to last a number of years, providing that the system receives minimal but regular maintenance. This installation does not need to be dismantled or shifted; it stays in place on a permanent basis and its automation makes it easy to manage.

The high initial investment and complexity of its installation have to be taken into account, and the return on investment is long-term. There are, however, numerous agronomic and practical advantages, namely: efficiency, discretion, less weeds, time-saving, sustainable use of resources.

Surface drip irrigation

This is the method most commonly used worldwide.

It is possible to install recyclable thin-walled tubes of the Streamline type (less than 250µm thick), which will be renewed each year. In this case, the investment cost is minimal but the running cost is higher. At the end of the season, the drip tubing is collected up and incorporated into the recycling system.

Thick-walled drip lines of the DRIPNET or UNIRAM type (greater than 1 mm), on reels, which can be stored and reused each year. The investment is higher initially but they do not have to be replaced each year. The drippers used are generally more efficient with a flow-control option at dripper level, providing uniformity across the whole irrigated area,

The drip lines are installed every other row, between the rows, with a spacing of around 1.4 m.

The tubes are laid at the 5-leaf stage. About 5 h/ ha is required in total for winding out the drip tubing and then for connecting it to the water supply line. Dismantling is quicker, requiring two people working 1.5 h/ha. i.e. 3 h/ha, carried out after the harvest. As far as the drip tape is concerned, laying out and removal is faster, gaining 1 h/ha per operation.

The laying and removal of the system is completely mechanised with the use of hydraulic machines for unwinding and winding in, allowing for up to 6 coils of drip coils to be wound out per run.

The proposed system was designed to make installation as easy as possible and to be completely removable outside of the irrigation period. The header lines can be made of very resistant Flexnet-type flexible braided tubing to allow the movement of farm machinery above the ground, which is very light to facilitate installation and storage.

To avoid leakages, it should include factory-welded built-in outlets for supplying water to the drip lines and, by using rapid and secure connections, there is maximum saving on time during installation. It is then simply wound back in and stored at the end of the season to be used again.

With its ongoing development over more than 30 years, the drip irrigation of maize (corn) now offers very practical solutions, which are easy to install and use. With a field irrigation system that is fixed and automated, it is very simple to manage for the producer and there is optimum saving on time.

With increasing pressure on water resources during the summer months, the efficiency of the irrigation methods used will be a key factor in society accepting the irrigation of maize (corn). Drip irrigation provides the best potential for saving water in this sector.

Apart from saving on water, the drip irrigation technology with very low operating pressures (around 2 bar) allows for substantial savings to be made on energy.

These savings on energy could be 50% more than that of the hose reel machines. Within the current context of increased energy costs, these savings make the device more and more competitive.

Fertigation gives the producer a significant competitive advantage.

This entails using the irrigation water for applying the nutrients to the plants, these being important for their growth. This allows for the fertilisers to be used more efficiently.

The “water + nutrients” solution is applied to the zone where there is most root activity. A good “air + water + nutrients” balance allows for the nutrients to be absorbed rapidly and efficiently. Thus excesses and deficiencies are very limited.

This is particularly true in the light of increased fertilizer costs and more stringent environmental standards.

The reduced amounts of fertilizer inputs applied means that the cost of the fertigation equipment is quickly recovered. All the more so as the investment is relatively low.

The main investment is incurred when buying the localized irrigation system.

Only a fertilizer injection system needs to be purchased for the implementation of this practice. The connection to the network is very simple, economical and easily automated. The irrigation network thus becomes a fixed and accurate distribution system.

The benefits achieved by using fertigation will vary.

However, the studies undertaken have allowed us to see the scale of the savings that can be achieved with this technique. The efficiency will represent the quantity of nutrients actually used by the plant compared to the quantity of nutrients applied by fertilization.

For Nitrogen it has been demonstrated that we gain about 40% on efficiency with fertigation.

For the Phosphates or Potassium, this gain is around 20%.

The energy crisis, which affects the cost of irrigation and fertigation, the reduced quantity of water resources available during the summer, problems encountered with labour management and stricter environmental standards, mean that this this production tool has to be the most efficient for the maize (corn) producer.

The irrigation and fertilizer distribution systems that use the drip technique represent one of the production tools that allow us to produce more with less.

For many years, these systems have been widely used in areas where water resources are already scarce. With climate change, the new areas of maize or corn production must be adapted to use these tools so as to be able to cope with these new environmental constraints.

We must not only look at this production tool in terms of profitability but also within the context of security.

Isn’t it better to pay a little more but have the comfort of being able to continue irrigating in a stable way by providing security for the yield, in spite of the dry summers?